As a professional writer, I am delighted to share with you the remarkable capabilities of gantry machining center and how it contributes to improving product quality and performance.

Unparalleled Precision and Accuracy

Gantry machining centers are renowned for their exceptional precision and accuracy. With advanced computer numerical control (CNC) technology, these machines can execute complex operations with utmost precision, ensuring that each component is manufactured to exact specifications. This level of accuracy significantly enhances the overall quality of products while minimizing errors or defects.

Efficient Production Process

The utilization of gantry machining centers streamlines the production process by automating various tasks. These machines can perform multiple operations simultaneously, such as milling, drilling, cutting, and shaping. This efficiency not only reduces production time but also minimizes human error during manual handling. By optimizing productivity, manufacturers can deliver high-quality products more efficiently.

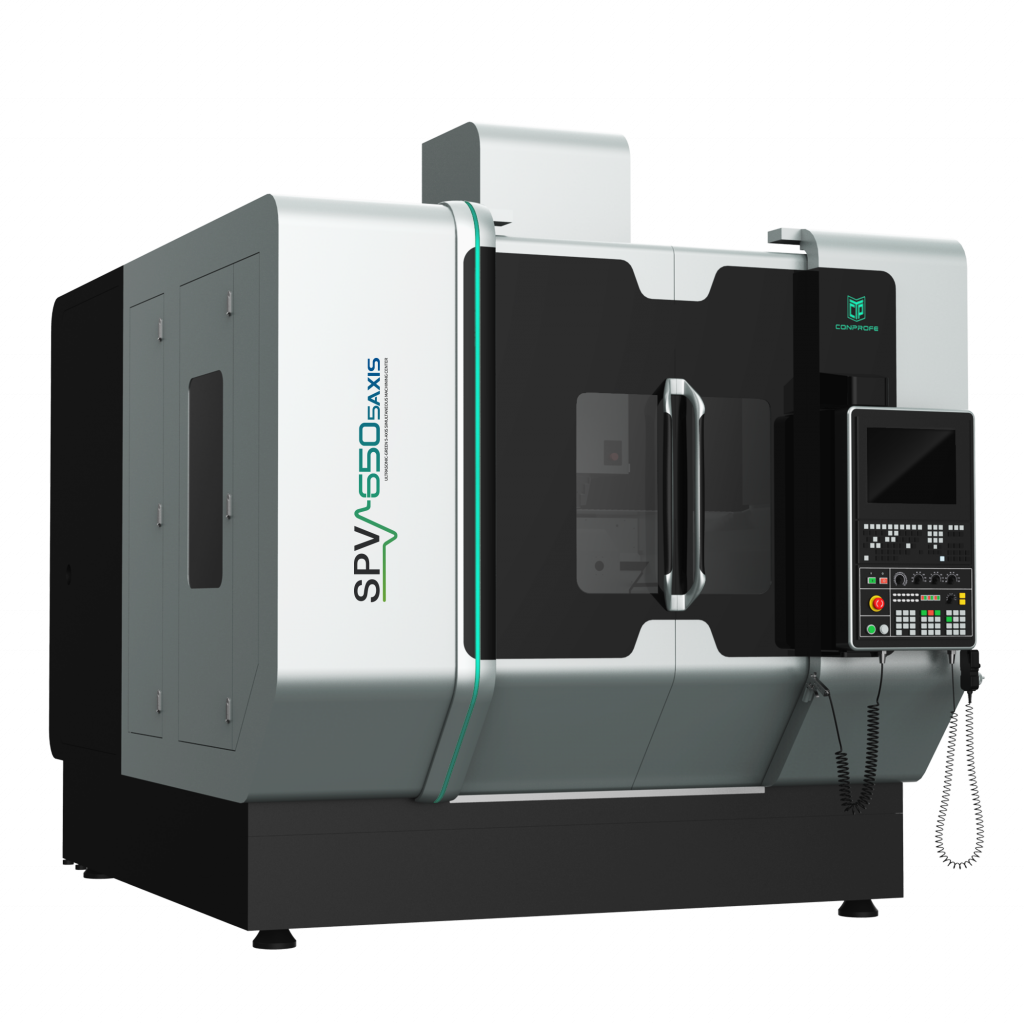

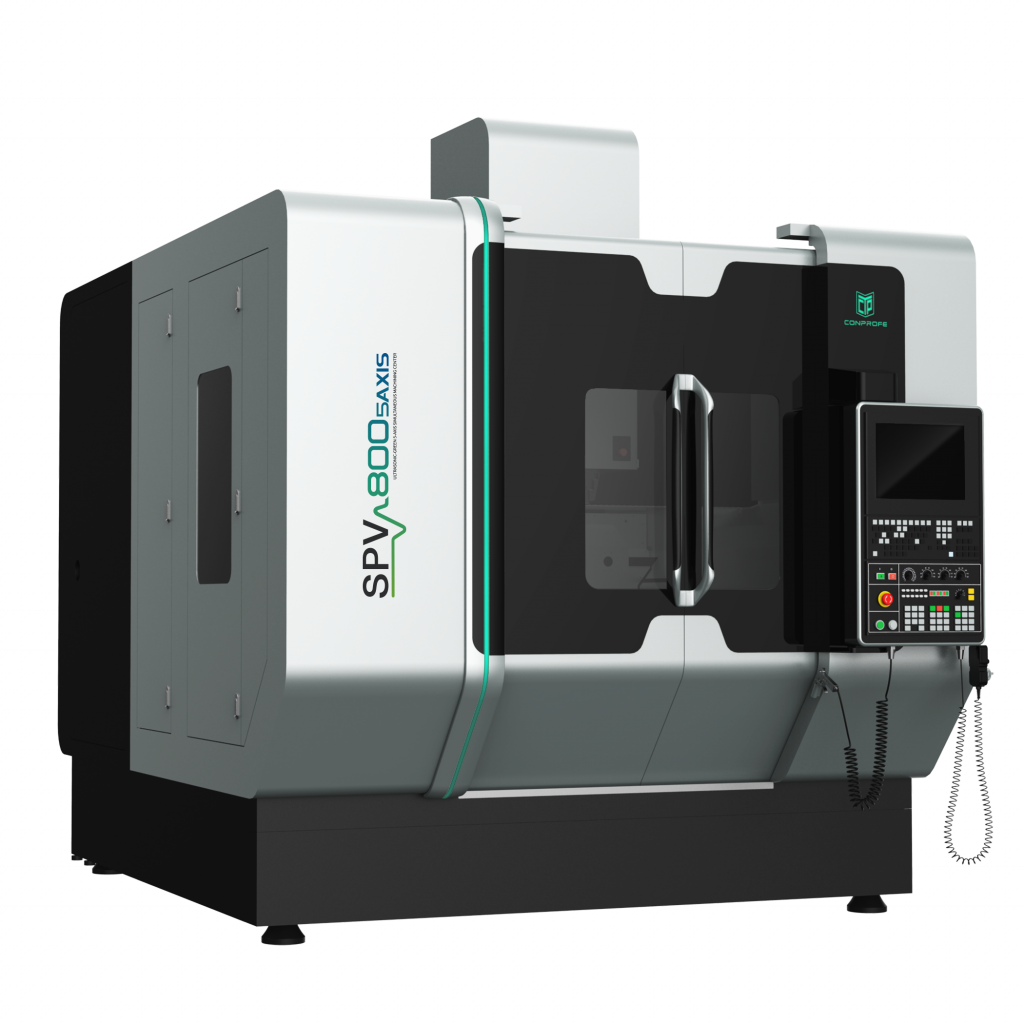

Innovative Conprofe Ultrasonic Technology

An exciting development in gantry machining centers is the integration of Conprofe Ultrasonic technology. This innovative feature allows for ultrasonic vibration-assisted cutting processes that result in improved surface finish and reduced tool wear. The combination of traditional mechanical cutting methods with ultrasonic vibrations offers enhanced material removal rates without compromising on precision or product integrity.

Premium Milling Machine Manufacturers

To ensure top-notch product quality and performance, partnering with reputable milling machine manufacturers is crucial. These manufacturers possess extensive expertise in designing and producing gantry machining centers tailored to specific industry requirements. They utilize state-of-the-art technologies along with rigorous quality control measures to guarantee reliable performance and durability throughout the lifespan of their machines.

In Conclusion

Gantry machining centers play a pivotal role in enhancing product quality and performance. Their unparalleled precision, efficient production process, integration of Conprofe Ultrasonic technology, and collaboration with reputable milling machine manufacturers collectively contribute to the delivery of superior products. By harnessing the capabilities of gantry machining centers, manufacturers can meet customer demands for high-quality products while staying at the forefront of technological advancements.